Waste Transformer Oil Administration Solutions for Environmental Compliance

The Duty of Dielectric Transformer Oil in Reliable Power Circulation Equipment

Dielectric transformer oil is a crucial element in the realm of power circulation systems, offering essential features that prolong past mere insulation. Its capability to protect against electric discharges and help with warm dissipation guarantees that transformers operate effectively and maintain their durability.

Functions of Dielectric Transformer Oil

Furthermore, dielectric transformer oil plays an important role in thermal monitoring. It successfully dissipates warm generated throughout the operation of transformers, facilitating optimum performance and extending devices life - waste transformer oil. The oil distributes within the transformer, soaking up warm and delivering it to cooling radiators or systems, thus maintaining a steady operational temperature level

Moreover, dielectric transformer oil adds to the prevention of oxidation and rust of internal parts. By offering an obstacle versus moisture and air, it protects the mechanical and electrical residential properties of the materials used in transformers, minimizing the likelihood of early failing.

Significance of Insulation

The stability of electrical systems greatly relies upon reliable insulation, which functions as the first line of defense against brief circuits and electric discharges. Insulation products, such as those used in cables and transformers, are important for keeping the operational reliability of power distribution systems. They stop unplanned current flow, safeguarding both equipment and workers from harmful electric failings.

The relevance of insulation expands past mere protection; it also guarantees the durability of electrical elements. Top notch insulation products can hold up against ecological stress factors, such as wetness, temperature level variants, and mechanical effects, consequently minimizing the probability of insulation malfunction. This durability is vital in maintaining the effectiveness of power distribution infrastructure.

Warmth Dissipation Mechanism

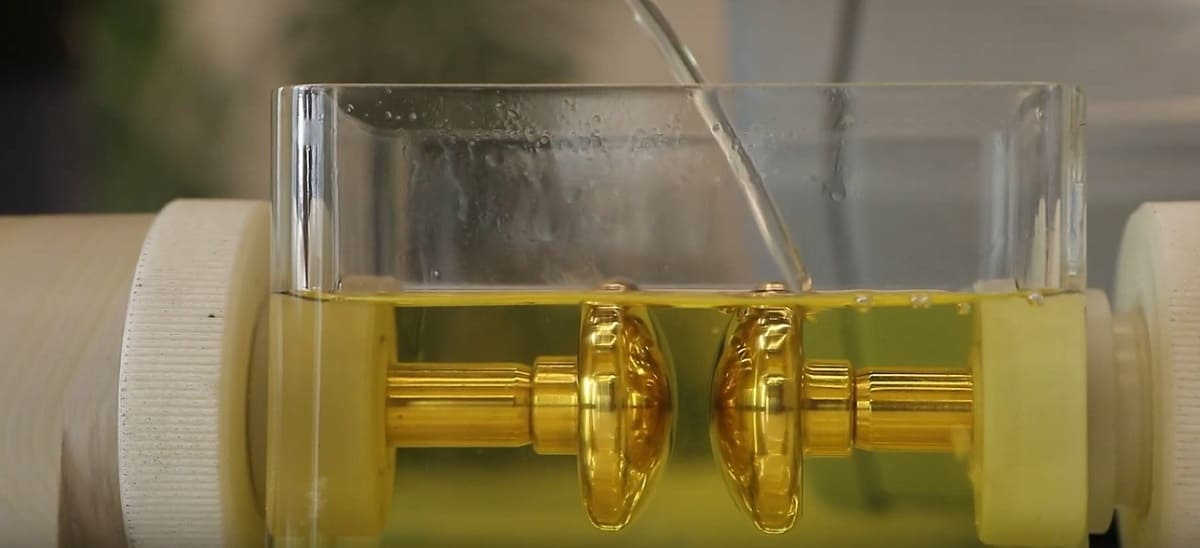

When considering the efficiency of power distribution systems, understanding the heat dissipation mechanism is important, as excessive heat can result in equipment failure and reduced functional lifespan. Dielectric transformer oil plays an important function in this process by helping with effective heat move far from essential parts within the transformer.

The key system of warm dissipation in transformers involves conduction, convection, and radiation. Dielectric oil performs warm away from the windings and core, enabling an extra consistent temperature distribution. The oil flows within the transformer, either normally or through forced circulation, boosting convective warm transfer. This circulation is essential, as it makes certain that warmth produced by electric losses is successfully carried to the cooler areas of the transformer.

Additionally, the dielectric residential or his comment is here commercial properties of the oil protect against electrical breakdown while supporting air conditioning. The high thermal conductivity of transformer oil allows quick warm exchange, ensuring that temperature surges are reduced (electrical insulating oil). By keeping optimal operating temperature levels, dielectric oil not just improves the integrity of power distribution systems however likewise contributes to the overall performance of power transmission. Comprehending these mechanisms is crucial for the optimal design and procedure of transformers within the power distribution network.

Influence on Transformer Long Life

Effective warm dissipation straight affects transformer longevity, as prolonged exposure to elevated temperature levels can increase insulation degradation and material fatigue. Dielectric transformer oil plays an important duty in this procedure by successfully transferring heat away from the core and windings, maintaining optimal operating temperatures. The thermal conductivity and particular warm capability of transformer oil are crucial characteristics that enhance its ability to absorb and dissipate heat generated during transformer procedure.

Moreover, the oil's dielectric residential or commercial properties are important for avoiding electrical break down and guaranteeing insulation integrity. A top quality dielectric oil decreases the risk of arcing and pop over to these guys dielectric failure, which can lead to tragic transformer failings and substantially reduce service life. Regular monitoring of the oil's problem is necessary to determine pollutants and degradation items that might jeopardize its performance.

In enhancement, the chemical security of the dielectric oil is critical; oils that resist oxidation and thermal destruction add to prolonged insulation life and total transformer integrity. By reducing the effects of warmth and electrical stress and anxiety, dielectric transformer oil acts as a vital component in enhancing the long life and performance of power circulation transformers, hence making sure a more trustworthy energy supply.

Ecological Factors To Consider

Environmental factors to consider bordering dielectric transformer oil are increasingly important in the context of lasting power circulation systems. The use of typical mineral oil provides challenges due to its potential ecological risks, consisting of poisoning to aquatic life, dirt contamination, and problem in biodegradation.

Moreover, the disposal and recycling of dielectric oil are essential elements of environmental stewardship. Correct administration practices need to be executed to avoid spills and leakages, which can have damaging impacts on neighborhood environments. Regulatory structures are evolving to implement stringent standards regarding the handling, storage space, and disposal of transformer oils, ensuring that energies focus on environmental honesty.

Additionally, the life process analysis of dielectric transformer oils is ending up being an essential element of evaluating their overall ecological effect. This evaluation consists of oil manufacturing, usage, and end-of-life disposal. By opting and adopting sustainable methods for eco-friendly choices, power distribution systems can substantially lessen their environmental footprint while preserving operational dependability.

Verdict

In verdict, dielectric transformer oil is crucial for the integrity and performance of power circulation systems. The oil's capability to reduce oxidation and corrosion enhances transformer long life, therefore minimizing maintenance costs.

Dielectric transformer oil is an important component in the world of power circulation systems, offering crucial functions that expand beyond mere insulation.Dielectric transformer oil offers numerous vital functions in power distribution systems, making certain both operational efficiency and safety and security. Dielectric transformer oil plays a critical function in this process by successfully transferring heat away moved here from the core and windings, keeping ideal operating temperature levels. The thermal conductivity and certain heat ability of transformer oil are necessary attributes that enhance its capability to soak up and dissipate warmth generated during transformer procedure.

A high-quality dielectric oil lowers the risk of arcing and dielectric failing, which can lead to tragic transformer failings and considerably shorten service life. electrical insulating oil.